INDIAN ARMED FORCES CHIEFS ON OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

The insightful articles, inspiring narrations and analytical perspectives presented by the Editorial Team, establish an alluring connect with the reader. My compliments and best wishes to SP Guide Publications.

"Over the past 60 years, the growth of SP Guide Publications has mirrored the rising stature of Indian Navy. Its well-researched and informative magazines on Defence and Aerospace sector have served to shape an educated opinion of our military personnel, policy makers and the public alike. I wish SP's Publication team continued success, fair winds and following seas in all future endeavour!"

Since, its inception in 1964, SP Guide Publications has consistently demonstrated commitment to high-quality journalism in the aerospace and defence sectors, earning a well-deserved reputation as Asia's largest media house in this domain. I wish SP Guide Publications continued success in its pursuit of excellence.

- All about HAMMER Smart Precision Guided Weapon in India — “BEL-Safran Collaboration”

- US to sell $93 million precision artillery, Javelin and Excalibur projectiles to India

- US to sell $93 million precision artillery, Javelin and Excalibur projectiles to India

- India, Germany deepen defence ties as High Defence Committee charts ambitious plan

- True strategic autonomy will come only when our code is as indigenous as our hardware: Rajnath Singh

- India-Israel Joint Working Group Meeting on defence cooperation to boost technology sharing and co-development

- G20 Summit: A Sign of Global Fracture

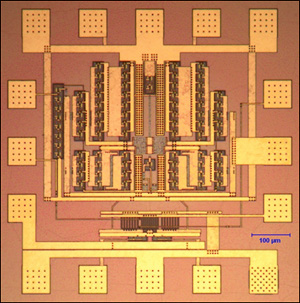

Integrated onto a Single Chip

DARPA begins efforts to bridge compound semiconductor and silicon integrated circuit communities

The Defence Advanced Research Projects Agency (DARPA) under its diverse accessible heterogeneous integration (DAHI) programme is launching the DAHI Foundry Technology effort to advance novel methods for combining a variety of devices and materials onto a single silicon chip.

High-performance microsystems are vital for a wide variety of DoD systems that provide US warfighters with technological surprise over adversaries in areas such as communications, sensing and electronic warfare. Current fabrication technology limits the types of materials and devices that can be integrated together, forcing circuit designers to make compromises when selecting devices for an integrated microsystem.

According to DARPA Microsystems Technology Office, enabling the ability to ‘mix and match’ a wide variety of devices and materials on a common silicon substrate would allow circuit designers to select the best device for each function within their designs. This integration would provide DoD systems with the benefits of a variety of devices and materials integrated in close proximity on a single chip, minimising the performance limitations caused by physical separation among devices.

This effort also seeks to enable complex signal-processing and self-correction architectures to be brought to bear. The DAHI Foundry Technology effort hopes to establish a foundry capability for the production of chips using a wide range of heterogeneously integrated devices.