INDIAN ARMED FORCES CHIEFS ON OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

The insightful articles, inspiring narrations and analytical perspectives presented by the Editorial Team, establish an alluring connect with the reader. My compliments and best wishes to SP Guide Publications.

"Over the past 60 years, the growth of SP Guide Publications has mirrored the rising stature of Indian Navy. Its well-researched and informative magazines on Defence and Aerospace sector have served to shape an educated opinion of our military personnel, policy makers and the public alike. I wish SP's Publication team continued success, fair winds and following seas in all future endeavour!"

Since, its inception in 1964, SP Guide Publications has consistently demonstrated commitment to high-quality journalism in the aerospace and defence sectors, earning a well-deserved reputation as Asia's largest media house in this domain. I wish SP Guide Publications continued success in its pursuit of excellence.

- MoD initiates comprehensive review of Defence Acquisition Procedure 2020, pushes for defence reforms

- G7: The Swansong

- Kalinga Connect: South Asia to Polynesia

- Must Credit DRDO for Operation Sindoor, now what is next for defence R&D?

- The layered Air Defence systems that worked superbly, the key element of Operation Sindoor

- Operation Sindoor | Day 2 DGMOs Briefing

- Operation Sindoor: Resolute yet Restrained

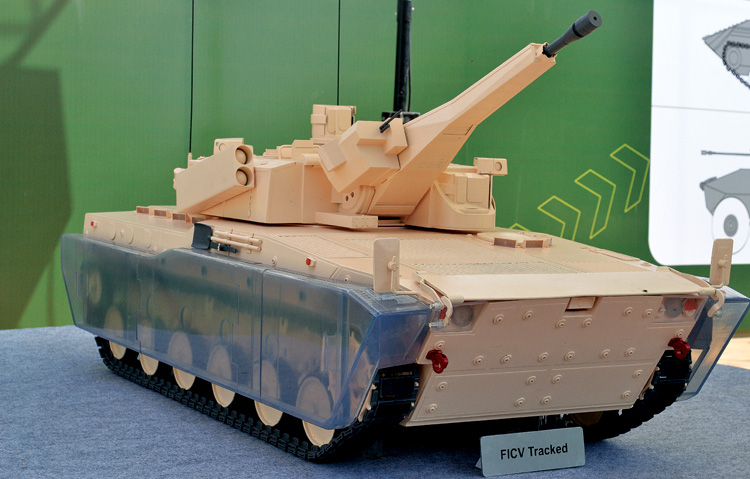

Future Infantry Combat Vehicle (FICV) Quagmire: Analysis of the Paralysis and Way Forward

Fourteen years of deliberation (2004-2018) and frequent changes in procedural stance have yielded miniscule capability enhancements in the BMP II fleet upgrade. This along with the FICV quagmire magnifies the capability void.

The story of FICV is a saga of illusions and a case study of wavering bureaucratic decisionmaking, compromising future operational capability and national security. Even before its design is conceptualised, its obituary seems to have been signed. Repeated procedural hiccups and lack of commitment/support for the project at apex approving level has resulted in more snakes than ladders in its turbulent case history. This has resulted in creating an operational void due to attendant time delay, escalating inflationary cost and uncertainty of assured budgetary support in the future. Termed as a game changer for an integrated defence ecosystem both for infrastructure development and high technology infusion, under the otherwise illusive ‘Make in India’, it had raised optimism in the nascent yet vibrant Indian defence industry. However, self-created ambiguities of its future have only multiplied, in an otherwise clean and clear EoI evaluation by Integrated Project Management Team (IPMT) submitted to MoD in November 2016 which should have paved the next step forward. This raises many issues in the “Pandora Box”. Has “Make-I” (and its earlier Avatar ‘Make’) already sounded the death knell with neither BMS, TCS and FICV progressing? Are those behind the scuttling effort, players who did not feature in the EoI of this big ticket? Is the recent bogey of possibly progressing it under Make-II (DPP 2016) pragmatic for a project which is technology intensive, time sensitive, operationally critical and an opportunity to invigorate the indigenous defence eco system through a competitive process? Who is responsible for the procedural delay and its impact since issue of its first EoI in May 2010 and is their accountability and institutionalisation in the otherwise wavering approach to critical defence procurement? How will this indigenous technological gap be managed and who will hold the IPR? Does it merit to be reviewed under the Strategic Partnership model? This article analyses some of these intriguing issues, aimed at evolving possible options and suggesting solutions to this quagmire.

The Operational Imperative

There have been transformational changes in the evolving geo-strategic canvas creating strategic uncertainty and volatility, impacting the global and regional security. In particular, in the last one decade, the security landscape in Indian subcontinent has changed dramatically with a volatile, radicalised and revisionist Pakistan brewing proxy war in India and a swaggering and intimidating Chinese expansionism undercutting the Indian sphere of influence. These along with evolving power centers of strategic realignments, mandate strengthening of all facets of our comprehensive national power, of which indigenous military power and deterrence is an important facet for strategic autonomy.

A modern Infantry Combat Vehicle (ICV) fleet is a critical component of the Mechanised Force as a means to ensure “Victory at Least Cost and in Minimum Time”

Combat vehicles are a critical component of a nation’s military capability building, across the entire spectrum which has stood the test of recent hybrid conflicts. National security especially with our turbulent borders’ mandates, that the Army must field new capabilities when they are required, not when they are expedient; modernisation efforts must match or exceed adversary advances. A modern Infantry Combat Vehicle (ICV) fleet is a critical component of the Mechanised Force as a means to ensure “Victory at Least Cost and in Minimum Time”. The ICVs are armoured vehicles which carry mechanised infantry into the battle as an integrated weapon platform, part of a combined arms team, across the entire spectrum ranging from a nuclear battlefield to a sub conventional domain. The FICV will be used to safely transport mechanised infantry to critical locations in battle field, provide fire support to cover their dismounted operations and destroy enemy tanks and other weapon platforms. Their ability to float across water obstacle as a mobile protected lethal platform gives them the singular critical operational capability to gain and retain execution tempo especially in a proactive strategy. While fighting against increasing capable and elusive enemies, maintaining combat overmatch requires ICV modernisation to support continuous time critical technological upgradation of current fleet and simultaneously innovative approach to development of replacement platforms with future capabilities. The Army thus requires both a new FICV and incremental technological improvements in the existing fleet of BMP II. This becomes the essence of a pragmatic long-term fleet management plan based on future threats and vulnerability analysis, risk assessment and desired capabilities for the combat fleet, balanced against a pragmatic budgetary forecast.

ICV Fleet Management Challenge

Presently the mainstay of the ICV fleet of the Indian Army is the BMP II inducted in mid 1980’s. With a service life of globally accepted formulation of 32 years, replacement by FICV in 2017-18 onwards was an operational imperative. However, neither has the BMP II seen major technological comprehensive upgrades in mobility, firepower and survivability; nor is the FICV on track. Hence the operational effectiveness of this large fleet of over 2500 platforms remains sub optimal with a glaring unresolved capability void. Even if the FICV as presently planned manifests in the Army by 2026-27, the complete fleet replacement will take minimum 13 years (@200 per year) i.e. by 2040; by when the first lot would be near mid-life and necessitating next level of upgrades. Any further delay will be at the cost of stretching this operational void from a state of risk to danger. This cauldron is a manifestation of “defunct procedure, weary decision making, and a neglected outcome” oriented approach. Fourteen years of deliberation (2004-2018) and frequent changes in procedural stance have yielded miniscule capability enhancements in the BMP II fleet upgrade. This along with the FICV quagmire magnifies the capability void. The result is that the Army continues to hold and produce an obsolete technology equipment on its operational inventory.

The FICV: A Turbulent Journey

The FICV began its turbulent journey through an AON(Acceptance of Necessity) in October 2009, under DPP 2008, Make Chapter, for a quantity of 2610 combat vehicles. Since 2009, the 60,000 crore FICV project has been launched twice through EoI’s in 2010 and later in 2015, each time with great promise, but wavering stance, commitment and lethargy at decision making level. The last EoI of July 2015 was evaluated in an objective, transparent and fair manner and submitted after nine months of intense and tedious evaluation by the IPMT, for approval of the MoD in Nov 2016. A sensitivity analysis and brainstorming of all contentious claims by vendors was meticulously done by IPMT to rule out any impact on the final result. The EoI evaluation criteria was based on commercial/financial strength, technical capability, critical technology and technical specifications in compliance to the operational requirement. Each criterion was assigned weightage based on a rationale and evaluation methodology evolved over a year’s deliberation with subject matter experts, user and statistical tools used to decide inter-se importance of criteria and parameters. Finally, the evaluation matrix was prepared and approved on file by MoD, and sealed before issue of EoI. The next stage involved nomination of two best Development Agencies (DA) besides OFB by MoD, for formulation of a Detailed Project Report (DPR) leading to the development of prototypes for trials. However, it is here that once again a paralysis set into the system for reasons beyond comprehension.

The impasse commenced with the same MoD office who had approved the EoI evaluation criteria, raising concerns on the approved parameters and weightages at this belated stage. This de-facto amounted to changing the goal post after results were submitted and thus could question the integrity of the system. Some wild card suggestions to give the DPR to all five EoI respondents and thereafter select two DAs based on DPR was logically, procedurally and legally not tenable. In the meantime, those vendors who were not respondents to the EoI or those who got jelly knees, apprehensive of a favourable outcome for them, joined the band wagon to raise irrelevant concerns aimed at scuttling the process by unbalancing likely competitors through false claims, finally aimed at retraction of the present EoI. The case was referred to a panel of Independent Expert Monitors (IEMs) by MoD, who conclusively found no merit in the complaints and the EoI evaluation was considered righteous to be moved to the next stage of nomination of the two selected DAs and OFB.

Having presumably overcome these initial setbacks of over 30 months of decision paralysis, the new lot of approving authorities now developed cold feet on the budgetary allocation to the two selected private industry DAs (80 per cent by Govt and 20 per cent by DA under DPP 2008) as development cost estimated (linked to milestones to be stated in DPR) was conceivably around 500 crore each. Once again, those private players not in the fray raised yet another bogey to sabotage the case by recommending progressing it under Make-II (DPP 2016), thereby enticing a fund starved MoD to save its initial development cost. This proposal raises more questions than answers:

- Is it legally justified to shift from Make (DPP 2008) to Make-II (DPP 2016) without retraction of the present EoI and recommencing the case from starter bloc?

- If the case is restarted from scratch by retracting present EoI, who will be responsible for any delay in this critical operational void and with this wavering approach is there any certainty of its survival even in future? Will Make-II move faster and will it deliver a successful indigenous FICV model for the user faster and better than where Make-I status stands as of date?

- FICV being the first high technology complex system under ‘Make in India’ initiative requires a system of system approach or just a system integrator approach. Thus, will the FICV under Make-II be “Assembled in India” or ‘Made in India’ with desired indigenisation content, rights /licenses, ToT and IPR under our control? Further, under Make-II, are there any guarantees for production and indigenous lifecycle support being leveraged by Foreign OEM rather than Indian OEM?

- Due to lack of expertise and experience of Indian private industry in the sphere of combat vehicles, domestic companies will go in for tie up with overseas companies in almost all critical/high technology areas. Since the prototype does not necessarily guarantee success of the project, will the Indian OEM and its foreign collaborator be willing to invest large amount for development cost and associated tie ups without assurances?

Why will FICV be a Game Changer?

The FICV will be a critical force multiplier for ensuring combat overmatch in the future conflict scenarios, across the entire spectrum of our envisaged threats and desired capabilities. Equally important, it would be a band wagon on which the large, medium and small scale defence enterprises could find mutually exclusive space for building an integrated defence eco system. Thus, it would act as a stimulant to boost the recently announced defence corridor from a concept to a reality setting aside all concerns of ‘Make in India’. The FICV also encompasses a family of combat support futuristic vehicles including scope for development the operationally needed light tank, based on the concept of commonality of base platform. Besides the large number of FICV and associated platforms required, which makes an exciting proposition, its life cycle management and support makes excellent business sense for both the Indian Defence Industry and foreign collaborators. Like the success story of emergence of IT hubs and automotive industry in India, this promises even greater potential for the future, provided we exhibit a strategic vision and demonstrated will, of not only being a net producer of our operational needs but also a net exporter of indigenous high technology weapon systems. FICV will be a harbinger of high-end technology induction to India. Its EoI encompasses five core technologies (Engine, Main Gun & Ammunition, Armour Material, Transmission & Steering and Running Gear) and thirty-four sub system critical technologies which account for nearly 32 per cent of the evaluation criteria. Given our nascent defence R&D base, low defence technology threshold and the DRDO experience, technology induction will have to be in collaboration with foreign OEMs, through a MoUs with complete ToT and leverage of IPR in the hands of Indian OEM. This may realistically transit from “Assemble in India”, to ‘Make in India’ to ‘Made in India’. We must learn our lessons from the OEM monopolistic tendencies under licensed production, like in the case of T-90 tanks. Thus, the Rights/license for commercial development, series production, continued engineering support and product improvement through joint R&D must rest with the Indian OEM. In essence the rights/license to manufacture, maintain, overall, exploit and upgrade must be with Indian OEM, thus mandating design ToT (the why), manufacture ToT (the how) and all material & sub system ToT, along with IPR maximum handles for strategic autonomy. Another important associated weakness that needs to be overcome prior is the ability to monitor and absorb technology by Indian OEM. Further, the offsets accrued through this venture must ideally galvanize the defence R&D base.

Spiral Approach to Matching the Operational Requirement and Addressing the Technological Gap

FICV needs to be user driven as per the defined operational capabilities which must be realistic based on mature technologies with scope for upgrade at production/midlife stage to emerging futuristic technologies. To cover the development period and associated technological gap, a spiral approach to technology enhancement is an imperative. Thus, the first prototype should be able to meet the Key Performance Parameters viz Essential Parameters (defacto mature technologies) and subsequent upgrades/development should include ‘Desirable Parameters’ (de-facto emerging technologies).’ The FICV presently envisages a platform (with a crew of three and a stick of minimum eight personnel with combat loads), that is air portable and amphibious with high mobility (Power to weight ratio minimum 25:1) over all terrains obtaining along our borders. It encompasses high lethality for destruction of enemy tank targets by minimum third generation all weather, day night, top attack capable missile system and a multi-purpose main gun/cannon for other ground targets and hostile helicopters. To counter the multiple threats in the battle space it seeks a multilayered all-around passive survivability kit as an essential criterion, with desirability of active protection system and stealth cum signature management technology solutions as upgrades. The challenge remains space, power and weight management without compromising its primary role as an amphibious platform. Finally, its high mission reliability, maintainability, adaptability to varied terrain and affordability will also be important governing factors.

It may also be prudent for the Army to consider its requirement of wheeled FICV variants especially for our Northern Borders, obstacle ridden terrain/marginal terrain like Rann of Kutch, amphibious operations and even possibly in counter insurgency/counter terrorist operations.

Way Forward: Options and Implications

The FICV is a critical operational requirement of the Indian Army which must manifest in enhanced combat capabilities in a time and technology sensitive progression. FICV programme has to progress because it will not be just be a lethal platform, but also be the base for other defence R&D programmes and a test case of the credibility of ‘Make in India’ initiative. The options for progressing it thus narrows down to three disparate procurement courses viz Make-I as presently ongoing, Make-II as being suggested by some vendors with vested interests or the recent Strategic Partnership model which is barely finding its feet.

FICV needs to be user driven as per the defined operational capabilities which must be realistic based on mature technologies with scope for upgrade at production/midlife stage to emerging futuristic technologies.

Option 1: FICV on Track under ‘Make-I’ (Make DPP 2008). Having deliberated thread bear since 2015, after learning lessons from the past, it’s time to show the moral courage and commitment to ‘Make in India’ by the MoD to progress the case. Any further delay must seek responsibility and accountability for its void in the operational capability and cost escalation. The Indian defence industry especially the big sharks also need to exhibit maturity, character and ethical behavior based on transparency and fairness of this big ticket. Even if financial support is becoming an impediment, it must be worked out mutually by MoD with selected OEMs and User for a staggered allocation of funds based on certain landmarks / milestones to be achieved. It would also give credibility to catalysing the recently announced defence corridors. The Army should also be supportive of such an option as it would get them the desired product with life cycle support in the earliest timeframe.

Option 2: FICV Shifted under ‘Make-II’. ‘Make-II’ procedure per se is a desirable addition to the DPP 16 but not for complex high technology and cost intensive projects. Thus, shifting FICV at this stage under ‘Make-II’ would be detrimental to timely fructification of the already delayed project with minimum three to four years’ time penalty in induction of FICV and no assurances of its success. Second time retraction of EoI will have strong negative impact on the credibility of MoD and its processes. Serious Indian vendors & foreign OEMs may thus lose interest and back out. The tall claims of few influential Indian vendors to fund D&D effort of estimated 400-500 Cr by themselves and as well as on NCNC (no cost no commitment) case seems to be a bogey to scuttle and eliminate fair competition/participation in the project. There are also strong apprehensions that once the current EoI is retracted and MoD decides to go for fresh AoN under ‘Make-II’, these (or all) vendors will request/pressurise MoD for many moderations/amendments/deviations in procedures to cut down their D&D expenditure. Likely moderations could be:

- Modify PSQR to match the existing ICV platforms so as to avoid major D&D efforts.

- Accept ex-import equipment for Field Evaluation (NCNC) or accept lowest possible indigenous content in the prototype (against DPP requirement of 40 per cent).

- Rights and Licence of Critical Technology are likely to get restricted in Make-II, against almost all 34 technology agreed in current Make-I EoI response. Each Critical Tech would have considerable cost for acquisition.

- Foreign OEMs possibly had agreed to part with/share Critical Technology to only those Indian Vendors who got selected through EoI evaluation as they were a 50 per cent chance to win the final contract under Make-I. With ‘Make-II’ being open to all, foreign OEMs may not guarantee any such support, thereby forcing Indian vendors to buy only products and not the Rights/Licence of Critical Technology. Any compromise on acquiring Critical Technology and their Rights/Licence would lead to dilution of category from ‘Make-II’ of D&D to mere ‘Buy & Make’ where only getting a product with ToT is the focus.

Option 3: Strategic Partnership (SP) Model as the New Avtar of FICV. SP was proposed by the Dhirendra Singh Committee in July, 2015 and guidelines approved by the DAC in July 2018. SP model aims to create a vibrant defence manufacturing ecosystem in the country through joint ventures between Indian corporates and global defence majors. The strategic partnership model seeks to identify a few Indian private companies as Strategic Partners who would tie up with a few shortlisted foreign Original Equipment Manufacturers (OEMs) to manufacture big-ticket military platforms. In the initial phase, the selection of SPs would be confined to four segments: Fighter Aircraft, Helicopters, Submarines, and Armoured Fighting Vehicles (AFV)/Main Battle Tanks (MBT). Strategic Partners, being private sector companies, are expected to exploit their dynamism, competiveness, profit orientation, and exposure to the civilian sector for efficient utilisation of the technology, manpower and infrastructure developed in the process. However, being a nascent entry into the system there are several concerns and loose ends which need to be tied up by MoD. While a good initiative for invigorating the defence procurement especially big tickets, FICV cannot be its testing ground having been delayed since 2008 and already ten years behind to address the critical operational void. In any case progressing the FRCV (Future Ready Combat Vehicle albeit the Future MBT) as being presently pursued, makes good sense and need not be joined by FICV to throw all the eggs in one basket. Currently, there are likely only very few existing ICVs which are closer to FICV requirement especially amphibious capability. These are K-21 (S Korea, 2010) and Krugnet-25 (Russian D&D project). Since there are not many proven track ICVs available, ‘SP’ or ‘Buy & Make’ are likely to result in SVC (single vendor case) and hence not recommended.

Analysis and Recommendations

Between SP and Make-II, both the routes will deny India self–reliance that we are aiming for, under ‘Make in India’. Both are essentially ‘Buy & Make’ procedures that will ensure that India remains dependent on the Foreign OEM not only during the production cycle but also the lifecycle maintenance, repair and overhaul (the cost of acquisition is normally one third of the entire lifecycle cost). Between the SP and the Make – II, why does the SP score better? The Make-II requires no solid guarantees for indigenous lifecycle support. Thus, subsequent MRO support may involve ‘off the shelf’ buy of spares and rotables involving costly forex and vulnerability to political arm-twisting. For the vendor this makes good business sense and for the user it is not only costly MRO but also dependence of foreign OEM for spares and thus an operational situation that user is trying to avoid in the first place. SP model on the other hand makes better sense because the Indian OEM has lifecycle costing built into its contract thus ensuring Indian OEM’s firm commitment to invest in the long term for cost cutting which is to his own advantage and thus makes better business sense. Moreover, while both SP and Make-II has no govt funding liability, the investment by SP is after he has been selected (i.e. when his order is guaranteed) as against Make-II where large No. of competitors are expected to make investment with no guarantee of orders/success. Is the Indian Defence Industry prepared to accept such risks? Hence prototype, if ever produced, will more or less be off the shelf with some cover up for Indigenous Content (IC). Forcing vendor to increase IC after he has won the competition is unlikely to yield result.

Both from the perspective of time sensitive indigenous capability development, as well as addressing critical operational void, it would be prudent to progress FICV to the next stage under Make-I route. MoD must not waste any more time and expeditiously progress the FICV case, with due responsibility and accountability.

Between the SP and Make-I, the latter binds the Indian OEM to commit to licenses (if not complete IP) for indigenous manufacture and subsequent MRO for supporting equipment lifecycles; and most important, indigenous upgrades (by Indian OEM at its best and jointly between the Foreign OEM and Indian OEM, at its worst), since it is initially paid for by MoD and later built into the contract.

Thus, Make-I scores better then SP model if the focus on is getting rights/license and indigenization. Between Make-I and Make-II, the Make-I procedure allows up-gradation of platforms throughout its lifecycle, replacing any redundant or obsolescent technology with that from indigenous sources or from the inventory of any third Foreign OEM as long as compatibility is ensured by the lead partner. Even Indian DRDO could be made to contribute during the lifecycle upgrade. No legal action can be brought against this replacement exercise as the IP for integration lies with the Indian side. Same is not the case with Make-II where the upgradation will be under the control of the Foreign OEM.

Thus, a comparative analysis and a reality check clearly establishes Make-I as a more pragmatic and advantageous option for FICV.

Conclusion

FICV programme must progress because it will not just be a lethal platform, but also be the base for other defence R&D programmes and a test of the credibility of ‘Make in India’ initiative. Both from the perspective of time sensitive indigenous capability development, as well as addressing critical operational void, it would be prudent to progress FICV to the next stage under Make-I route. MoD must not waste any more time and expeditiously progress the FICV case, with due responsibility and accountability.

The author recently retired as Director General, Mechanised Forces, Indian Army.